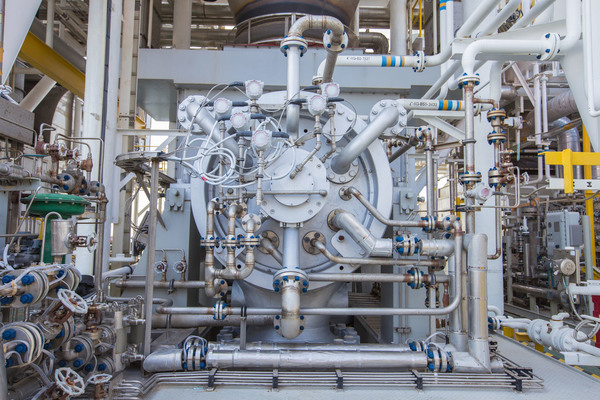

Compression Systems

Compression systems are often required for various applications within gas processing facilities, typically for use in the following:

- Gas Lift and Re-injection

- Gathering, Transmission and Storage

- Gas Turbine Fuel Boosting

- Floating Production, Storage and Offloading (FPSO)

OSL have extensive knowledge and experience working with gas compression systems for these applications, our experience and knowledge spans back from the systems and technology used 25 years ago to the latest technology used today. OSL are familiar and have experience designing and specifying the following equipment commonly required in a gas compressor package:

- Conventional straight-through and inter-stage cooled centrifugal compressors

- High speed hermitically sealed centrifugal compressor with magnetic bearing systems

- Turbine generator driven compressors

- Variable Frequency Drive systems

- High speed electric motor driven compressors

- Lube oil systems

- Dry Gas Seal systems

- Anti-surge control

- Air cooled after-cooling

- Shell and tube heat exchangers

- Piping systems design

- Electrical and control systems

Typically equipment is designed in accordance with the relevant national and international codes and standards, these include BSI, EN, API, ASME and ISO standards. The OSL team have an extensive working knowledge of the relevant standards used for designing and specifying gas compression systems in order to deliver optimal safe working solutions.

OSL have and continue to work on numerous gas processing facilities worldwide, providing the following services in regards to compression systems:

- Complete compression system process design, equipment selection and sizing

- Specification of offshore and onshore installations

- Delivery of conceptual studies, FEED studies and EPC contracts

- Vendor liaison and procurement management

- Technical assistance and management of construction and commissioning activities

- Technical support to operation and maintenance activities on existing compression installations.

- Design and management of compressor modifications, including complete re-wheeling (change out of compressor internal bundle).