Liquefaction

In the liquefaction process, natural gas is cooled to minus 161 degrees Celsius through a refrigeration process, reducing the volume by a factor of 600. This reduction in volume makes it economically feasible to transport natural gas using LNG tankers. The process covers the phases of compression, condensation and expansion of one or more refrigerants and their heat exchange with the natural gas.

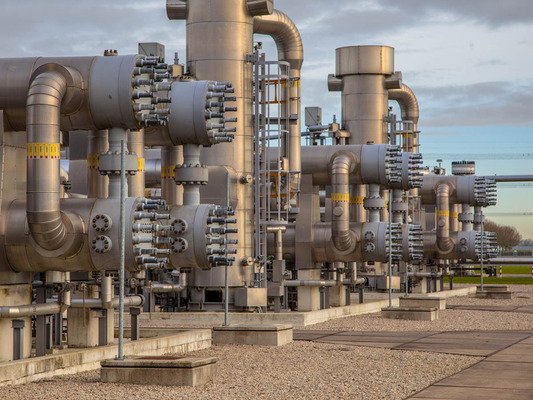

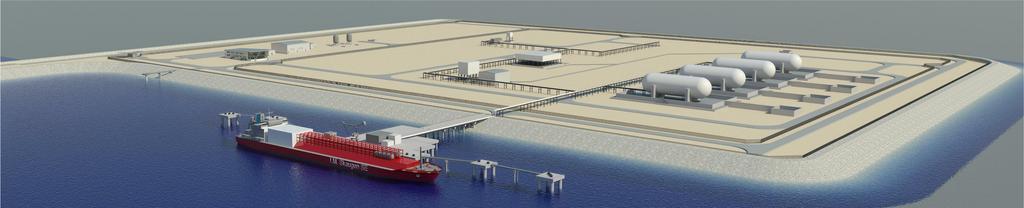

Liquefaction plants are made up of specific natural gas treatment installations as well as various auxiliary installations for steam production, seawater pumping or refrigeration along with LNG storage and loading facilities.

There are a number of technologies on the market that enable natural gas liquefaction depending of the size of the plant. The drivers of technology selection available, revolves around delivering the refrigeration in the most efficient and cost effective way using various combinations of refrigerants and fundamental thermodynamic cycles.

OSL has experience in the design and engineering of processes used in liquefaction facilities including:

- Pre-treatment processes, e.g. Receiving and Gas Metering, Acid Gas Removal, Dehydration, Mercury Removal.

- Refrigeration: Mixed Refrigerant Processes and Expansion Technologies.

The multidisciplinary team at OSL provide our clients with the following services and solutions:

- Liquefaction technology/process selection for LNG economics and technical feasibility

- Equipment design for refrigeration (compressors, drivers, gas turbines, heat exchangers, heaters, coolers), storage and transportation of LNG, e.g. storage tank, barges, jetty, loading/unloading arms

- Debottlenecking of existing plant system and marine systems, including BOG management

- Stress Analysis and Computational Fluid Dynamics for LNG vapour dispersion modelling

OSL considers factors such as simplicity (low equipment count), modularisation, ease of maintenance, operation and installation as the factors that play the most important role when selecting a liquefaction technology.

Our commitment to develop and engineer the right solution for liquefaction facilities has led us to evaluate the use of equipment that improve energy efficiency and reduce power consumption. OSL is focused on cost effective options generating solutions with a much lower CAPEX and OPEX so as to provide greater return on your investment and shorter payback time.